Zhejiang Xingda Electronic Technology Co., Ltd. was founded in 1999 and is a national high-tech enterprise and a specialized, refined, and new enterprise in Zhejiang. Its four subsidiaries specialize in eight major businesses, including structural components, hardware components, precision molds, process accessories, valves and instruments, wire harness connectors, water meter actuators, gas meter motors and valves. We have over 20 years of experience in customized development, providing integrated design and ODM/OEM solutions for development and design, manufacturing and molding, assembly and printing, surface treatment, testing and packaging, and providing one-stop service to customers.

QQ chatProvide from injection product design - precision injection mold processing and manufacturing - injection molding - 24-hour online after-sales service

Product development and design

Product development and design Precision die manufacturing

Precision die manufacturing Injection molding mass production

Injection molding mass production After sales one-stop service

After sales one-stop service

With more than 50 engineering mold design teams and more than 20 years of product design experience, it can accept customized drawings and samples, with a large amount of free mold design and free 3D proofing.

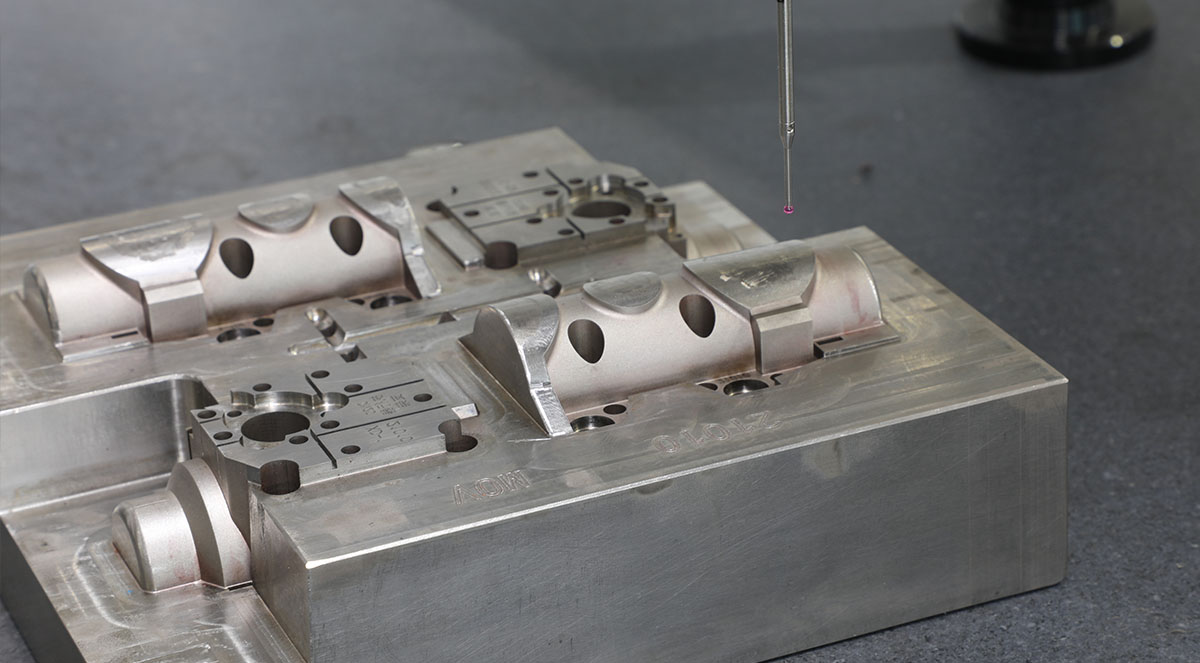

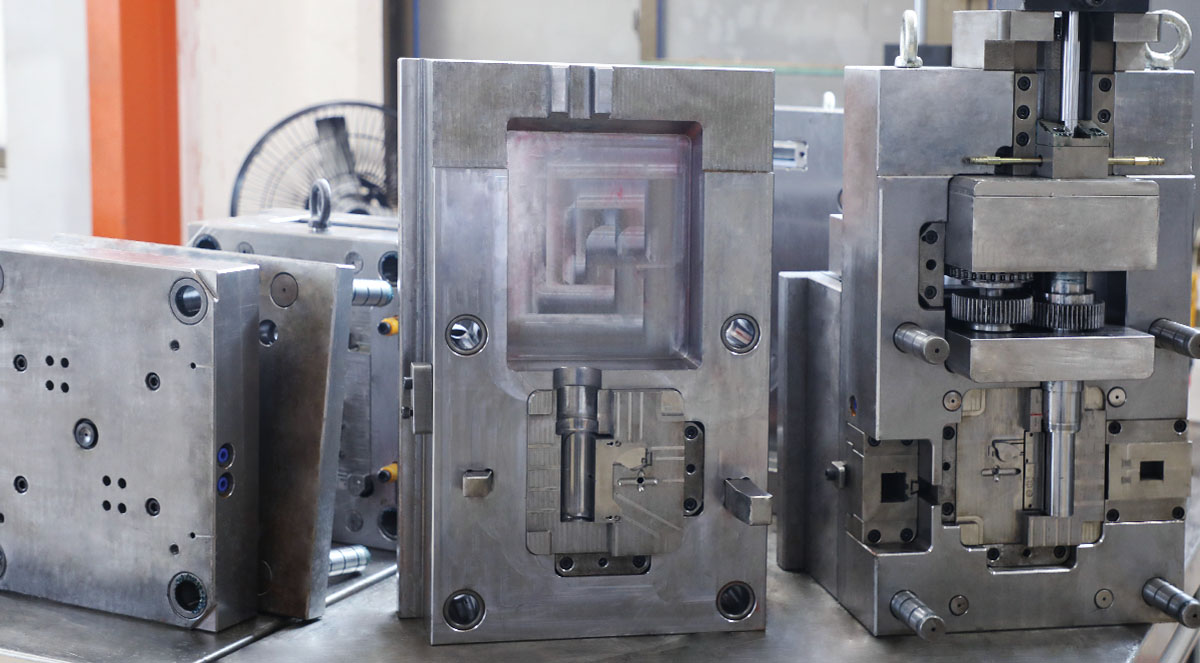

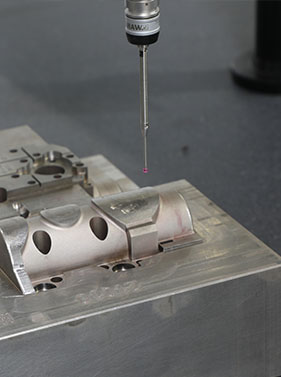

It has high-precision mold processing and testing equipment such as CNC wire cutting, full closed-loop wire walking, EDM, CNC numerical control, piercer, process grinder, bench drilling machine, turret milling machine, universal rocker milling machine, height measuring instrument and projector, which can timely complete the mold opening time and quality required by customers.

It has a complete production management team and perfect equipment, injection molding, silk screen printing, spraying, electroplating, bronzing, finished product assembly, mass production and shipment, and has assisted hundreds of customers to successfully achieve mass production.

Each project of the factory is specially connected and followed up by a specially assigned person, 24-hour online service, 2-hour product quotation speed, and customer feedback is fed back and solved within 2 hours. Any quality problem after the sale of the product shall be returned and replaced.

Good at structural optimization of high-precision injection molding parts, which can reduce the processing cost of injection mold by 50%

It can provide market research and competitive product analysis according to customer needs, with original design as the core, or optimize the structure of injection molded parts according to 3D drawings or samples provided by customers, so as to realize the efficient combination of design and structure

Customers can provide drawings, samples or individual needs. Xingda has a rich design team in the industry, which can provide drawings, optimized design or original design.

It has the rapid verification technology through 3D printing, which can shorten the early development time and development cost of products, and the fine features can reach 0.02mm. It can print breathable metal mold parts with controllable pore size

It can provide a complete set of solutions from product design, precision plastic mold processing and manufacturing, injection molding and assembly, and after-sales service

Ensure continuous and stable injection molding production and accelerate mass production and delivery of products

A total of 16000 square meters of production base, 2 in Wenzhou and 1 in Hangzhou. The company introduces advanced mold processing equipment and modern mold processing center.

It has medium and high-end precision mold equipment, one-stop customization, 60 high precision injection molding machines, and the injection molding workshop realizes the whole central feeding system.

The factory has a production team of 350 people, with engineering department, tooling department, injection molding department, stamping department, quality inspection department, packaging (assembly) department, etc

The delivery time is 7 days with goods in stock and 7-15 days without goods in stock. The finished product warehouse is 5000 + square meters, which can handle large orders from customers

Master the core technology and strictly control the processes of plastic mold processing

Precision die

Precision die Full time team

Full time team Quality control

Quality control Precision die manufacturing equipment

Precision die manufacturing equipmentThe medium and high-end quality must be precision die manufacturing. The injection mold factory has precision die manufacturing equipment, which can control the precision tolerance of customer accessories to 1 wire

Full time quality control team

Full time quality control teamIt has a full-time quality control team and engineering technology team with more than 20 years of experience. The production process is in strict accordance with the quality management system as the standard. Each product has undergone strict full inspection and meets the national testing standards

8 strict quality control links

8 strict quality control linksFrom material selection - > Production - > Inspection - > Distribution - > Each link is closely monitored and each process is fully inspected to ensure that the product qualification rate reaches 99%

With 20 years of cooperation experience with top 100 brands and integrity, Xingda is willing to cooperate with you for a long time

Focus on precision mold customization and injection molding

Focus on precision mold customization and injection moldingZhejiang Xingda Electronic Technology Co., Ltd. was founded in 1999 and is a national high-tech enterprise and a specialized, refined, and new enterprise in Zhejiang. Its four subsidiaries specialize in eight major businesses, including structural components, hardware components, precision molds, process accessories, valves and instruments, wire harness connectors, water meter actuators, gas meter motors and valves. We have over 20 years of experience in customized development, providing integrated design and ODM/OEM solutions for development and design, manufacturing and molding, assembly and printing, surface treatment, testing and packaging, and providing one-stop service to customers.

StrengthCustomization of precision injection molded parts

TailoredProduct design / mold manufacturing / injection mass production solution

Quality assuranceCheck at all levels and strictly control each link

After-sale serviceRapid docking of experienced teams